Residual Gas Analyzer Probe Design

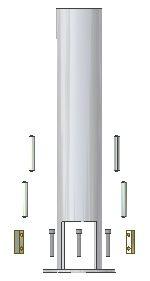

The probe consists of an ionizer, quadrupole mass filter and detector. While adhering to the most stringent ultra high vacuum standards, the novel design optimizes RGA, Pirani and ion gauge performance. The rugged probe assembly mounts onto a standard 2 3/4 inch CF flange. The end of the probe extends 6.8 inches (173 mm) from the mounting flange face. It requires no added vacuum extension nipple. Such a nipple (Extorr model number N-500) may be used give the user a required clearance in the vacuum system. The probe is designed using self-aligning parts and may be easily reassembled after cleaning.

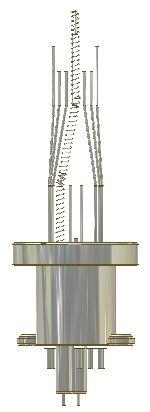

Dual Thoriated coated Iridium Filaments can be replaced in the field. They are vacuum degassed at 900 degrees C.

Ionizer is one piece, vacuum brazed with built in B/A gauge for accurate total pressure measurements. Materials used are 304 Stainless steel, Molybdenum, platinum and vacuum tube grade braze material. The source grid is constructed from platinum coated molybdenum wire. When it comes out of the vacuum furnace, it has been vacuum degassed at 900 degrees C.

The mass filter is constructed from alumina and stainless steel and can be easily cleaned and refurbished if contaminated. It is vacuum degassed at 500 degrees C.

The faraday detector assembly is made from stainless steel and alumina, vacuum brazed and degassed at 900 degrees C.

The frame that holds the above parts together is constructed from stainless steel and is also vacuum brazed and degassed at 900 degrees C. There are only 4 set screws, 3 other screws and 1 nut that hold the entire probe together. The number of fasteners were purposely kept to a minimum to decrease the chances of one coming loose during normal use.

The vacuum feedthrough is constructed from stainless steel, alumina, Kovar, nickel and is vacuum brazed at over 900 degrees C. It is then helium leak tested. The vacuum seals are ceramic to metal and will withstand repeated bakeout cycles. There is a pirani gauge in the base of the feedthrough and also a platinum RTD fastened to the base so that the temperature of the feedthrough is monitored by the software during use. The probe can be baked to 350 degrees C. without the CCU attached and 100 degrees C. while in operation. The CCU securely fastens to the probe with 2 thumb screws.